High Speed Stud Roll Froming Machine

1. Specification of the material

| 1 | Suitable Material | Galvanized steel |

| 2 | Width of the raw material | According to the final profile |

| 3 | Thickness | 0.3-1.15mm |

2. Machine Detailed Parameters

| 1 | Roll Forming

| High Speed Stud Roll Froming Machine

|

| 2 | Machine structure

| Wire-electrode cutting |

| 3 | Total power | About 70kw |

| 4 | Roller stations |

About 18 stations + one station of embossing

|

| 5 | Productivity

| 0-70m/min |

| 6 | Drive system

| By gear box |

| 7 | Diameter of shaft

| ¢60mm ,40CR tempering |

| 8 | Voltage

| 480V 60Hz 3phases (Customized) |

| 9 | Color Of The Machine

| Yellow and blue |

| 10 | Deliver Time

| 70 days |

| 11 | Terms Of Payment

| 30%T/T 70% pay before shipment |

3. Profile drawing

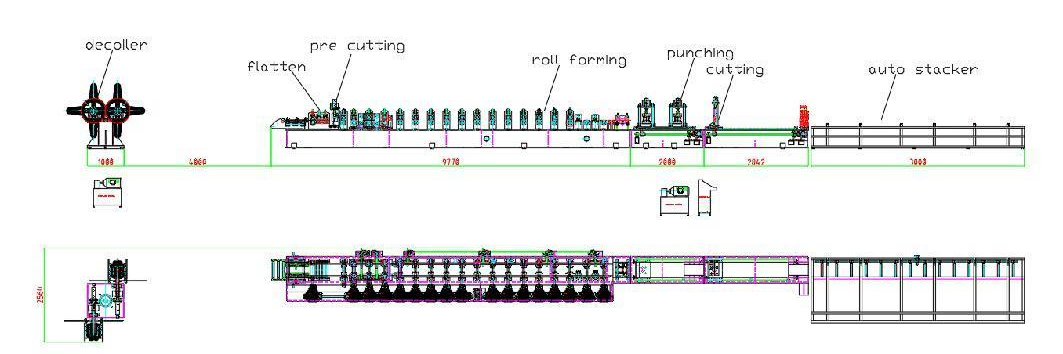

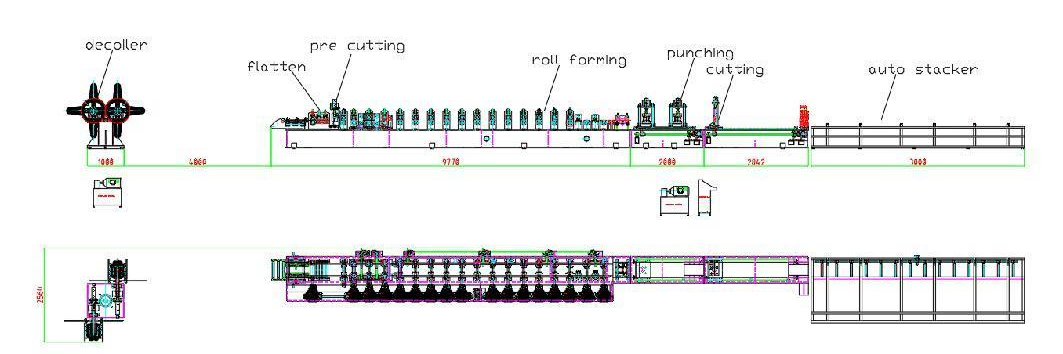

4. The Chart of Process Flow

5T double head hydraulic decoiler--Flatten--pre-cutting--roll

forming--tracking punching(2units)--track cutting--Conveyor--Flip

stacker

5. Specification of Components

(1) 5T Double head hydraulic decoiler

- Steel coil width: 500 mm;

- Internal diameter of coil: variable, from480 mm to 520 mm

- Maximal out diameter:1500mm

- Maximum coil weight: 5000 Kgx 2

- Main poer: 5.5kw

- Hydraulic power: 4kw

- Quantity: 1

(2)Feeding& flatten

Feeding

- Adjustable center of the forming rollers and of sufficient length

to prevent lateral movement of the strip entry to roll forming.

- Feeding type: adjustable

- Feeding width: according to the final profile

Flatten

- The quantity of leveler rolls must be planned according to

thickness 0.35mm to 1.15 mm.

- Flattener roller: upper is 3 rollers, down is 4 stations(total is 7

rollers)

- Leveling roller:40cr HCR50 °,diameter of roller about 60mm

- Way of working: active work

(3) Main Roll Forming Machine

- Roller material:CR12mov surface with chrome, HRC58-62 degree

- Shaft diameter: ¢60mm material: 40CR with tempering

- To avoid accidents, the driven parts will be covered with the

protective cover

- Cooling system is included

(4) Machine Structure

- Main frame by 350H beam welding

- Machine structure: Wire-electrode cutting

(5) Track punching& cutting system

- Machine adopt track punching and cutting system, Non-stop

- Two units punching system punching together

- Cutting power by hydraulic, 18.5KW with storage tank and cooling

system

- Track cutting by servo motor, power in 5.5KW

- Cutting after forming: Cut the sheet after roll forming to required

length

- Cutting motion: The main machine is NON-stop when cutting

- Material of blade:Cr12mov with heat treatment 58-60°

(6) Computer Control Cabinet

- Programmable setting of profile length and quantity

- Operating system language: English and Chinese

- Computer used to control length & quantity. Machine will

automatically cut to length and stop when required quantity is

achieved

- PLC: Panasonic or customerization

Usage:

a. Put the raw material(steel plate) through the beach to

manufacture and process,it can guarantee that the products are

neat, parallel and everything is uniformity.Please refer to the

equipment regulation to know the function of locate angle iron.

b. In order to keep the product shape and precision, adopts welded

sheet structure, motor reducer drive, chain

transmission,roller was chromed which can keep the molding plate

surface smooth and not easy to be marked whenit is working

c. Feature : Ensure stability , precision and lifetime.

Advanced hydraulic drive, automatic punching and cutting after

forming, no distorting or wasting, high level safety factor.