0.8 - 1.2mm Steel thickness Ceiling Roll Froming Machine / Roll

Former With Manual Decoiler

For Keel roll forming machine, everyone has different special concerns about it, and what we do

is to maximize the product requirements of each customer, so the

quality of our Keel roll forming machine has been well received by many customers and enjoyed a good

reputation in many countries. Zhangjiagang City Saibo

Science&Technologu Co.,Ltd. Keel roll forming machine have characteristic design & practical performance & competitive

price, for more information on the Keel roll forming machine, please feel free to contact us.

Normal Speed Stud Roll Forming Machine

1. Composition of machine

Roll forming main machine……………………………1 unit

Manual Un-coiler……………………………………… 1 unit

Control panel…………………………………………..1 unit

Hydraulic station…………………………………… …1 unit

Out table ………………………………… ……………2 unit

Spare tools……………………………………………...one box

2. Machine Detailed Parameters

| 1 | Roll Forming

| YX70 |

| 2 | Coil width

| According the profile |

| 3 | Rolling Speed

| 0-15m/min |

| 4 | Rolling Thickness

| 0.8-1.2mm aluminium alloy steel |

| 5 | Control System

| PLC |

| 6 | Un Coiler

| 3 ton manual un-coiler |

| 7 | Roller Stations

| 8 stations+1 station of film system |

| 8 | Roller Material

| 45 forge steel, surface with chrome |

| 9 | Shaft Material and DIA

| ¢56mm, material is 45# forge steel |

| 10 | Maim Motor Power

| 5.5KW |

| 11 | Hydraulic Station Power

| 4KW |

12

| Hydraulic Pressure | 12Mpa |

| 13 | Cutting type | Hydraulic cutting, 4kw

|

14

| Material Of Cutting | Cr12, quenching 58-62℃ |

15

| Tolerance | 3m+-1.5mm |

16

| Electric Source | 380V, 50HZ,3 phase According to customer’s require |

17

| Way Of Drive | By chain |

18

| Color Of The Machine | Yellow and blue |

3. Profile drawing

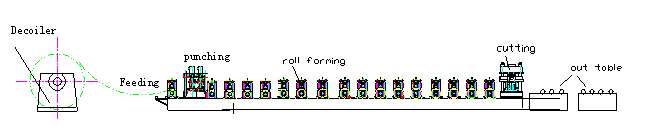

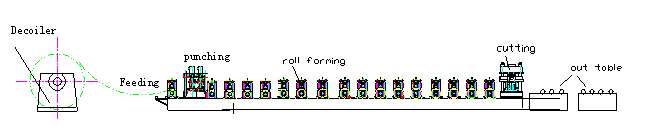

4. The Chart of Process Flow

5. Specification of Components

(1) 3T Manual Un-coiler

- Adopt automatic hydraulic system for expand

- Width of feeding: 350mm

- Capability: 3 Ton

- Bound of expand &fight: 380mm—520mm

- Mode of expand &fight: inner expand &fight by manual

- Way of feeding: manual

(2) Main Roll Forming Machine

- Machine adopt film system in order to protect the coil

Roll station: 8stations+ 1 station of film system (according to the

final design

Material of roller: 45#forge steel, coated with chrome

Material of main shaft:45﹟forge steel diameter roller: Ф56mm

Main power: 5.5kw

Forming thickness: 0.8-1.2mm, aluminium alloy steel

Transmission: By chain, 1.0inch, single line

(3) Post cutting system

- Machine adopt hydraulic cutting

- Cutting after forming: Cut the sheet after roll forming to required

length

- Cutting motion: The main machine automatically stops and the

cutting will take place. After the cutting, the main machine will

automatically start.

- Material of blade:Cr12 with heat treatment 58-60°

- Length measuring: Automatic encoder length measuring

- Tolerance of length: +/- 1.0mm

- Cutting table length: 2m

(4) Computer Control Cabinet

- Programmable setting of profile length and quantity

- Operating system language: English and Chinese

- Computer used to control length & quantity. Machine will

automatically cut to length and stop when required quantity is

achieved

- PLC: Panasonic or customerization

FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are

optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas

services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control

complies with ISO9001. Every machine has to past testing running

before it's packed for shipment.

5) How can I trust you that machines pasted testing running before

shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our

factory.

6) Q: Do you have this roof panel roll forming machine in stock?

A: No, machine is made to order.