0-15m/min Normal Speed Floor Deck Roll Forming Machine 22KW Drive

by Chain

1. Specification of the material

1. Sutiable Material: PI/PPGI

2. Width of the raw material: 1220mm

3. Thickness: 0.9mm-1.3mm

2. Machine Detailed Parameters

1

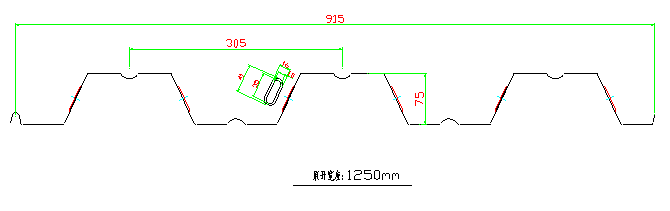

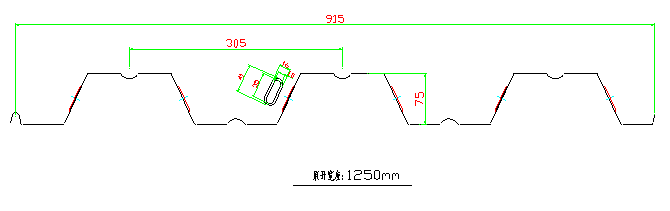

| Roll Forming Machine | YX75-305-915 |

2

| Machine structure | Wall board structure |

3

| Total power | Motor power-22kw Hydraulic power-5.5kw |

4

| Roller stations | About 20 stations |

5

| Productivity | 0-15m/min |

6

| Drive system | By chain |

7

| Diameter of shaft | ¢85mm solid shaft |

8

| Voltage | Customized |

9

| Color Of The Machine | Yellow and blue |

10

| Container need | 40HQ container |

11

| Deliver Time | 70 days |

12

| Terms Of Payment | 30%T/T 70% pay before shipment |

3. Profile drawing

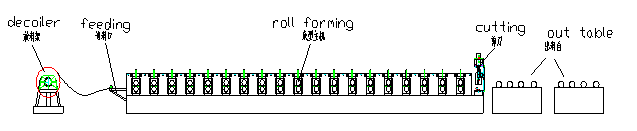

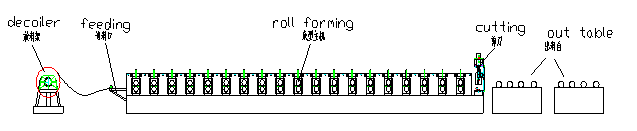

4. The Chart of Process Flow

5. Specification of Components

(1) 10T Hydraulic Un-coiler

- Width of feeding: 1250mm

- Capability: 10 Ton

- Inter diameter: 470-550mm

- Maximal out diameter: 1500mm

- Main motor power: 7.5KW

- Hydraulic power: 5.5kw

(2) Main Roll Forming Machine

- Roller material: ASTM1045 chrome plated surface with hardness

- Shaft diameter: ¢85mm material: SAE1045

- Machine structure: wall board

(3) Hydraulic cutting system

- Cutting after forming: Cut the sheet after roll forming to required

length

- Uses two hydraulic cylinders for operation.

- Material of blade:Cr12, 58-62 HRC hardness

- Cutting power by hydraulic,5.5KW

(4) Computer Control Cabinet

- Programmable setting of profile length and quantity

- Operating system language: English and Chinese

- Computer used to control length & quantity. Machine will

automatically cut to length and stop when required quantity is

achieved

- PLC: Panasonic or customerization

6.Usage: Put the raw material(steel plate) through the beach to manufacture

and process,it can guarantee that the products are neat, parallel

and everything is uniformity.Please refer to the equipment

regulation to know the function of locate angle iron.

Usage: In order to keep the product shape and precision, adopts welded

sheet structure, motor reducer drive, chain transmission,roller was

chromed which can keep the molding plate surface smooth and not

easy to be marked whenit is working

Feature : Ensure stability , precision and lifetime.

r.